So, after over 2000 miles in the car, it was time to address one of its biggest niggles… low temperature stalling.

Ever since I’d built the car it would stall at low engine temperatures. It would stall as I sat on the drive putting my harness on, it would stall at junctions for the first 4 or 5 miles and it would stall if gear changes were taken too leisurely. It needed a good 90-95C showing on the temperature gauge before it would idle anything close to ok. And even then it would occasionally stall when I de-clutched at junctions or changing gear.

The car was a real PITA to drive for anyone else and the final straw came when a co-pilot had a minor shunt after he’d stalled when pulling away from a junction – new rear wing needed! I’d got a few other events in 2019 set where other people would be driving the car and so it needed to get sorted.

What Needed to Get Done?

By this time I’d convinced myself that the car needed an ECU remap, it seemed as though the ECU was failing to “catch” the drop in revs as the engine speed dropped on a de-clutch when it was cold. But it also stalled when started from cold, so something was afoot!

I had the tick-over set at about 900 rpm, so I didn’t think it was that. I could certainly stop the stalling by increasing the tickover to something more like 1200 rpm, but that seemed like too much of a workaround. What seemed to make things worse was the light flywheel action… revs seemed to drop too quickly for the map to react to the drop.

Now, Caterham’s supplied ECU mappings don’t get a good rep on the internet forums or Facebook. And because the ECU map is locked then you need a new ECU if you want it remapped. That was going to set me back at least £500 for an ECU plus the cost of getting it mapped, probably on a rolling road. And of course all the talk on the internet had convinced me that this was what was going to be needed.

Then in a rush of common sense, I decided it would be a good idea to get someone who knows what they’re doing to have a look. But who?

Millwood Caterham

I don’t have a great deal of experience with Catherham servicing so I turned to the Internet for help. It seems that The Two Steves, Dave Gemzoe or Northampton Motorsport would be good places to go, especially for a remap. But I wanted something closer to home and hopefully less expensive.

I got the car from Williams originally and they had done the Post Build Check. I don’t have anything against Williams, but the fact that this stalling problem had not been picked up at the PBC and the desire to try someone new, led me to Millwood in Dursley, Gloucestershire. I gave Eric a call at Millwood and the car was booked in about 2 weeks later, early June 2019 (Eric was away for part of that time so couldn’t be any earlier).

Here’s their promo picture from their website (millwoodcaterham.co.uk)…

I turned up to Millwood after a quick early morning run up the M5. Millwood’s showroom is not particularly difficult to find but it’s tucked away behind a petrol station. The showroom probably holds about a dozen Caterhams and has a single bay workshop at the rear of the place.

Eric was working on another car when I arrived but was straight out to meet me and we got into talking about what needed to be done.

Because the stalling was only really happening when cold we decided to have a go at a flat-floor setup to let the car cool down a bit before looking at the stall problem. So, we rolled the car into the workshop bay and onto the 4 mobile weight scales.

Flat Flooring

Now, of course, I’m new to all of this, so if this is all old-news to you then you might want to skip ahead. Or, if I’ve got it wrong then let me know.

But for the novices amongst us, the idea of a flat-floor setup is to get the weights of each corner of the car about equal when you’re sat in it. It’s a bit of a misnomer that this has to be perfect, as the weights are going to change as you corner and the desired setup’s going to need to change if you’re tracking the car, depending on the circuit and for instance whether it is a clock-wise or counter-clock-wise circuit (more rights or more lefts respectively).

Eric was working on getting the left and right sides the right height and then diagonal weights about equal. With me sitting in it, clearly the LF/RR diagonal was going to be heavier than the RF/LR diagonal, but he thought my car was about as good as we were going to get. He changed a couple of the damper settings a little, but not that much in the end. It didn’t seem as thought Eric has a particular set of ratios or settings in mind, he looked at what the first set of readings were and worked from there. Though maybe I’m doing him a disservice!

He did give the front OS a 0.5 degree toe-in which he says helps with road driving and steering feel a bit, but I might not notice much. I also had about 7Kg of tools and “emergency” stuff in the boot which we had to remove.

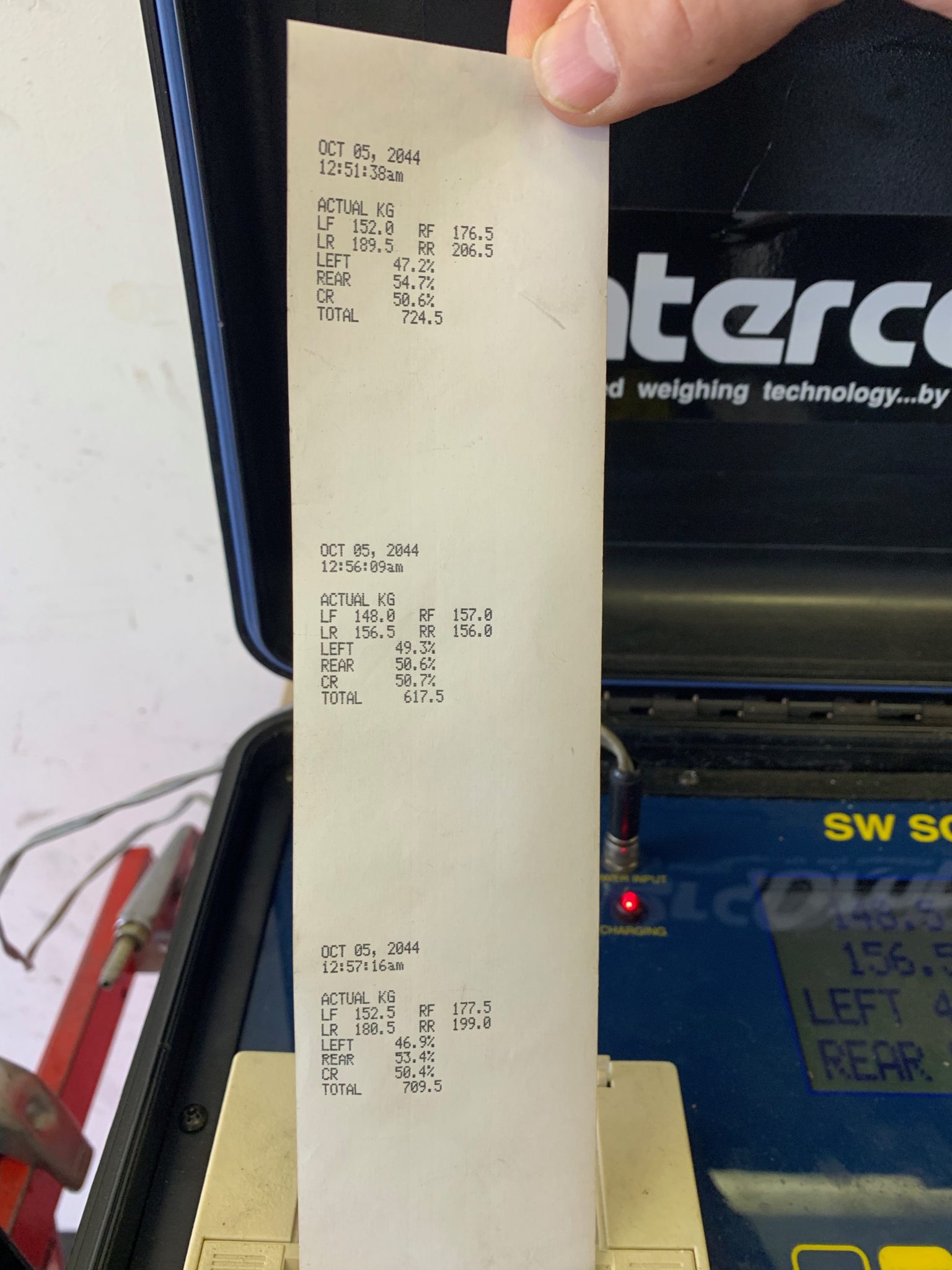

Here are the eventual weights:

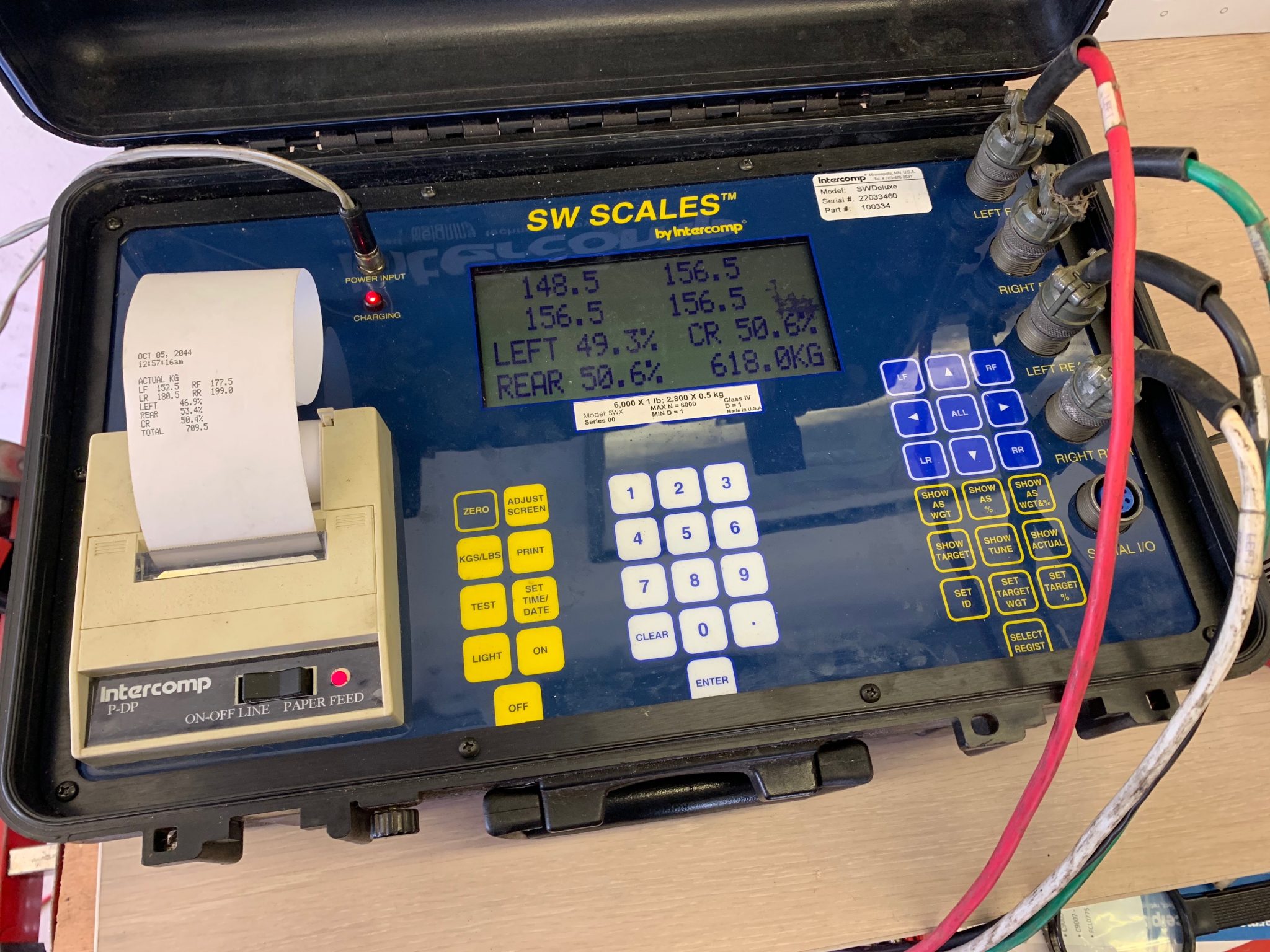

and here’s the machine:

Now, to interpret the (middle set) of weights, the LF, RF, LR and RR are obviously each corner weight. The “Left 49.3%” is the LF and LR added together and taken as a percentage of the total weight of the car:

(148.0 + 156.5) / 617.5 = 49.3%

It’s slightly heavier on the right… not a surprise, the exhaust system and steering column are on the right for a start. The “Rear 50.6%” is the Rear/Front split, which is a lot more even than I thought it would be, I thought it might actually be front heavy, but the engine is quite a way back in the frame I guess. Then the “CR 50.7%” is showing that the LR/RR diagonal is 50.7% of the total weight.

I was a little surprised at the 617.5Kg total weight. With about 15Kg of fuel (20L) and we assume 210bhp, then we’re actually at about 350bhp/tonne. Still respectable but not the headline 420bhp/tonne that Caterham would like you to think. On my car its the heater, leather seats, carpets etc that are all adding up.

It’s also interesting that with me sitting in the car, 75% of my weight (67Kg/89Kg) goes to the rear of the car. That makes sense of course, I’m sitting way closer to the rear wheels than the front, but its interesting to put a number on that. And almost the same can be said of my weight being added to the right (63/89 = 70%), again making sense but interesting to see the numbers.

After a few tweaks that was the suspension set up. Eric only dropped the front slightly in the end (about 5mm) and adjusted the dampers slightly to get the diagonal weights as seen in the last set of readings. It would take the ride home in the car to tell if anything felt different.

Stalling Problem

Now onto the stalling problem. Eric sat in the car and fired it up. It died. He fired it up again and it died again.

So Eric has seen on ton of these and he went straight to what he thought the problem was. He set about adjusting the tickover to be just below 1000rpm. Doing this reasonably quickly so as not to warm the engine up. That took a minute maybe.

Next Eric sat in the drivers seat and turned on the ignition, disarming the immobiliser and proceeded to repeatedly turn the ignition from position 1 to position 2. I’m pretty sure it was 1 to 2 and back again, rather than 0 to 2 and back, but I’ll have to check that.

As he was doing this he explained that the ECU often gets the “zero” position of the throttle potentiometer incorrectly set. If you play with the idle screw or if it becomes mis-configured (he didn’t go into why that might happen) then you need to go through this procedure again:

So the ECU reset procedure for a factory Duratec should be:

- Set the idle tick-over to just less than 1000rpm (I’ve heard that Catherham suggest 950)

- Turn ignition to position 2 and de-immobilise the car

- Repeat ignition position 1 to position 2 and back again 10 times

This procedure tells the ECU to remember this new potentiometer value to be the zero “home” position for the throttle. It may also do other things like reset the TPS sensor and do things with the Lambda sensor but I’ve found no discussion on the internet yet about that for Duratecs. Also note that this seems to be a different procedure than for K-Series cars – with those there’s a procedure that involves depressing the throttle 5 times while the engine is off but the ignition is on (see Google for exact instructions).

Once Eric had done this he fired the car up again and it didn’t immediately die. It tried to a couple of times but after a couple of quick blips to the throttle it sat idling, better than it had ever done cold.

And that was it.

While all this was happening, Eric and I had drunk coffee and talked a lot about the history of Millwood: how they used to be the Caterham dealership until Williams took over, how Eric used to be the 2nd for Burns in the WRC and how he and Jon had come to an agreement that Eric would work for Millwood after giving up his separate servicing business (seemed to be a lot of running of various rally cars for himself and for privateers since leaving Subaru).

We finished up and I set off home again after being there for about a couple of hours.

It’s also interesting to note that while I was there, Eric took a couple of telephone calls and helped those people out. There was also another customer that was negotiating a crisis that showed up and Eric helped out while I was there too. There didn’t seem to be any formalised process for this, just helping customers with their cars.

Conclusions

As I write this, I’ve put another 700 miles on the car in about 2 months since visiting Millwood. The car now feels more “sure footed” in corners and less dithery on the straight ahead, that was noticeable within the first 200m of leaving Millwood. I suspect that’s the toe-in that Eric didn’t think I’d feel much. The steering is probably a little heavier and there’s more confidence in how it drives and on straights it seems to stay on-track rather than wandering around like it did before.

As for the stalling. It’s much, much better. But still not perfect. It takes a couple of minutes of warming up in the mornings now before it will not die at a junction. Also the occasional stall at a junction and between gears has almost completely gone. I’m going to try the reset procedure again myself when the engine is really cold, see if that makes difference.

It’s also so much more pleasant to drive. I hadn’t appreciated how much low down go the car has. I can now happily do a rolling drive through a junction without having to heel-and-toe and slip the clutch. It pootles around town now without the kangarooing I was getting and I often short shift, missing a gear now from 2nd to 4th or 1st to 3rd, because its so much easier to drive.

This all now makes complete sense, if the ECU doesn’t know where the throttle is then it’s not going to be able to set the correct mapping.

For the moment, the need for a remap has gone. I still find it a bit unnerving how the engine revs drop so quickly when de-clutching, but at least the ECU catches the drop now before a stall. The light flywheel is also a pain if you want to pootle – gearshifts have to pretty quick not to need a blip going up the gears and if you’re too quick you’ll beat the gearbox and crunch a gear.

The clutch is also still pretty fierce and there’s not much to be had from starting off in 2nd (unless you’re on a down-hill) seeing as you’ll burn the clutch trying to make a clean getaway. So, for me, always start off in 1st, make sure your gear changes are quick, but not fast, and keep it in a higher gear around town. A quick point about that, in Bristol where I live, almost everywhere is set to 20mph, there’s very little point in attempting any spirited driving or else you’ll loose your license. I’ll leave the spirited stuff to some safe open roads and the track.

FWIW, I always heel-and-toe the throttle on a downshift – with that engine burble, why wouldn’t you. It’s also how I drive all manual cars, so why not this one.

In the end less than a couple of hundred quid for some time with an expert, a coffee and a chat was well worth it from my perspective.

Millwood are highly recommended.

[ PS: Thanks to Mark from Caterham7Diaries.com for spurring me into action and getting some more posts out. He’s got a great site by the way]

Leave a Comment