It was going to be “back to the coolant system again” today. I had left the car at the point where we’d started the engine but were worried about the coolant temperature getting well over 100C, something like 105C. We then chickened-out, turned it off and decided to ask Derek.

So I emailed Derek and this is the thread we got into…

Temperature Email thread to Derek

Hi Derek,

we managed to get the engine going on our build at the weekend. We had a bit of a problem with the inertia switch (even after resetting it and hearing it click) but once we’d taken it off and “had a look at it”, it all seemed to work from then on.

Anyway, question: we’re finding that the car is getting to over 100C when sat in the garage – light revving but obviously no load. The radiator is getting mildly hot at the top but not at the bottom, implying we probably have the thermostat slightly open. The heater is pumping out hot air when we open the valve and turn the blower on. All other pipes seem to be getting as hot as they should.

Is this normal and we just need to let it get up to 110C or something before the thermostat opens fully. I’ve heard Duratec’s run hot anyway and the standard Caterham shipped thermostat only opens at over 100C.

Also, the fan is not running at that temperature. We’ve isolated the fan and hooked it up to 12V, and it runs fine.

Suggestions?

Hello John,

Sorry I haven’t got back but I was off yesterday, it sound like you have an airlock in the system, when you filled the system did you remove the bolt on top of the rad as this can help, the fan will not come on until the temp is around 100 anyway.

Kind regards

Thanks Derek, I thought you might have been off.

Yes, I removed the bolt on top of the engine and let fluid run out of it. It certainly feels like I have an air-lock but I can’t put my finger on it at the moment. I’ve removed a few of the higher pipes and haven’t got it yet. My next plan was to take off the bottom radiator hose next to the thermostat in case there was air just before the thermostat. After that I’m not sure what to try but I’ll get there. I just needed you to say it sounds like an air lock and I’ll keep going.

Any news on the bonnet?

OBD-II

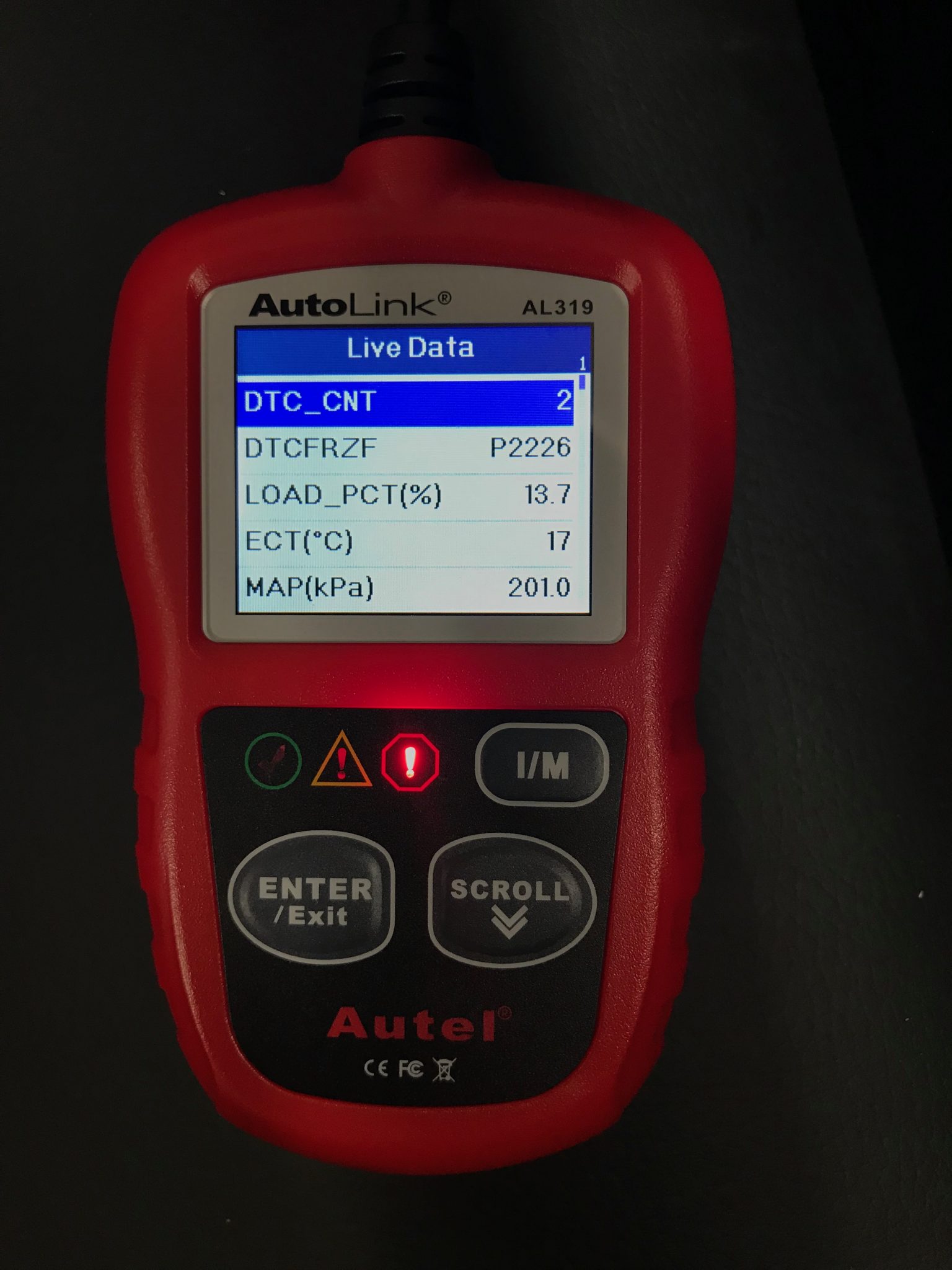

So I went and bought a cheap OBD-II data scanner from Amazon (AutoLink AL319). It also does fault reset stuff but I’m not so interested in that at the moment.

This is the first of 11 screens the OBD-II reports, I’ll do a bigger post on OBD at a later date… when I’ve got some real data from it and some miles under my belt. The OBD port is under the dash, cable-tied to the steering column assembly.

On a quick fire-up of the engine the OBD gadget was reading about the same as the analogue dashboard gauge.

Long story long… this got me to the point where, today, I could start to have another look at whether I had a coolant air-lock. Even with Derek’s re-assuring words I had not had the fan cut in or the thermostat open yet and before getting the car up to temp again I wanted to make sure there were no air-locks and I was performing a good test.

Throttle Pedal Position

But before that, I started the day off with a simple job… setting the throttle pedal position. My reasoning being that if I had to have the car running for a period then I might end up sitting in it keeping it ticking over. Having the throttle pedal working would make sense. I had already set the tick-over the previous weekend when we ran it up for the first time, so that didn’t need to be looked at again.

I then “yanked-to-fit ™” the pedal with a philips screwdriver inserted down the shaft of the throttle pedal until the cable in it’s slack position just fit snuggly into the throttle pedal. I had made sure that the cable, when slack, allowed the throttle to be fully shut. And at the other end of the scale I made sure that pulling the throttle cable so the throttle was fully open meant that neither the lower or upper throttle pedal limits came into play. I set the throttle pedal position, by bending the shaft, so it “just” created some positive tension in the cable… i.e. it wasn’t slack when fitted, nor did the pedal pull the throttle open at all.

Coolant Air-Lock Hunt

So, on with the hunt…

We’d looked at most of the places we thought there might be an air-lock the previous weekend but I wanted to go through them again and spend some more time on it.

First up was to see if there was anything locked around the heater pipework. This is the highest point in the plumbing system and therefore I thought naturally somewhere air would collect. However, my hunch was that, if anywhere, there was an air-lock around the rad-bottom-hose or thermostat but I wanted to start with the simple stuff first and not have coolant everywhere.

Next up (or down) I lowered the rear of the car to see if I could shift any air-locks that way.

I also tried the other option, nose down, rear up.

At this point I decided to fire the engine up again and see how I was getting on letting it get up to temperature.

The primaries were all getting equally hot and the head to around 180C…

The gauges were reading about 103C when finally the top radiator hose got properly hot…

Then the fan kicked in at around 107C…

Oil cooler was showing around 85C at the point the fan cut in…

It’s also interesting that the 5/16th hose from the rear of the cylinder head is pumping coolant to the header tank…

Ok…. So… now everything seems to be running ok. The thermostat seems to open just over 100C and the fan cuts in at around 107C.

… but I hadn’t really done anything. There had been no sign of any air-locks in the heater pipework and no sign of any air when I’d pulled various hoses off and put them back on again. There was also no drop in the coolant level in the expansion tank as I jiggled the front and back up and down (which might have indicated air moving into the expansion tank from the pipework). In the end I think we just weren’t brave enough getting the engine up to temp.

Having done a bunch of research on the Duratec engines, this seems about right. The high running temp is meant to help emissions and the coolant system is clearly set up to be pressurised at over 100C. While I’m not so worried about emissions I worried that the cooling system is up to its job.

Another Email to Derek

Hi Derek,

I got the engine running for an extended period today. Its sits at about 105C on the temp gauge. At a steady tickover the thermostat is open and the fan cuts in an out to regulate the temp. Does that temp sound right? In the end I don’t think there were any airlocks. I did a couple of hours trying to find air in the system before leaving it to run for long, but in the end I don’t think there was much in there (I’ve done a lot of plumbing along with bleeding air out of old bangers, so reasonably familiar with air locks 🙂 ).

I’m wondering if the thermostat might have stuck on for the first run and perhaps thermal cycling it got it going? Is that likely or something that happens?

On the way to getting the water sorted I did a lot of research this week on the water systems on Duratecs. I did a bit of an in-depth (that might be an understatement) blog post on it. Complete with animated 3D renderings! I’d appreciate you giving it a once over if you have time. It might also be something to point other people at if you feel the editorial is good enough. Feedback appreciated. The blog post is here:

Hello John,

Your animation is very good and everything looks to be going where it should be, I might use this myself.

Kind regards

Now, the big question is whether this running temp is too high for normal operation, let alone track days. Will high load mean we get thermal overrun when we stop after a track session and the fan is unable to keep the temperature down?

The only controls here are to a) fit a lower operating thermostat (85C) and/or b) add a bigger, higher capacity fan. The worst case appears to me at the moment would be after a track session and then sitting the car still with no airflow over the radiator – only the fan cooling the system. In this scenario I don’t think it will make much difference having the thermostat set to 85C vs 105C. The coolant will be getting to a high temp anyway and if the fan isn’t big enough to take the excess heat away from the engine then it won’t matter a great deal about whether it starts at 85C or 103/5C for the thermostat to open. On the fan size, sure that might help if there’s thermal overrun but I’m not planning to to change that at the moment. I guess there’s a third parameter here, potentially the fan operating temp could be set differently in the ECU, but that would need an aftermarket ECU – to my knowledge you can’t change anything like that in the Caterham ECUs. Again, just having the fan cut in earlier probably won’t make a big difference to things if the whole coolant system can’t cope with the track-load-and-stop scenario…. temperatures will run away no matter what. I presume this is all part of Caterham’s design thinking so I’m not too worried that I’m going to get into trouble with my initial light road use or even a timid first attempt at a track day.

I’m also wondering if a Duratec runs better when its hot or when it’s not so hot. I see lots of posts on forums where people switch out the factory fit thermostat for an 85C “race” thermostat. It’s not obvious whether this is for 2.0L Duratecs, wet or dry sumps with oil coolers, etc etc. Does having an 85C thermostat mean you get to a temperature equilibrium at a lower point than with a 105C thermostat? Is there thermal runaway and having an 85C stat mean you can run longer as the runaway builds? There’s clearly also a thermal gradient set up from the radiator all the way through to the internals of the block and head… does having an 85C thermostat mean you get a more optimal temperature in the block/head than when running a 105C thermostat at high load??

I’m new to this level of theory around engine running temps. Clearly you don’t want temps so high that you get pre-ignition or fueling problems on the inlet side (though running injectors is probably going to be easier than having a carburettor setup – due to increased fuel pressure?? – that’s a guess). And clearly there will be a point where the pressure release valve on the expansion tank will operate and possibly cause boiling in the system as pressure drops. I’ve heard stories of cylinder heads eroding due to micro-boiling where hot spots are created due to insufficient coolant flow… that needs more research too.

Hmmm. Lots to think about. My natural inclination is to put sensors everywhere and grab some real time data – but that’s another project.

Something to keep and eye on then, but for the moment I think the coolant system is working as intended. We need to be getting on with some more of the cosmetic stuff now…

Leave a Comment